COMMON SOLDERING ISSUES

Following are common soldering issues that may occur during solder training or production operations.

Pad Contamination (1)

Cause: Inadequate removal/cleaning of flux residue after reflow.

EPEC

Correction: RMA flux residues must be removed from the

assembly. On some assemblies or locations, no-clean fluxes

must also be removed.

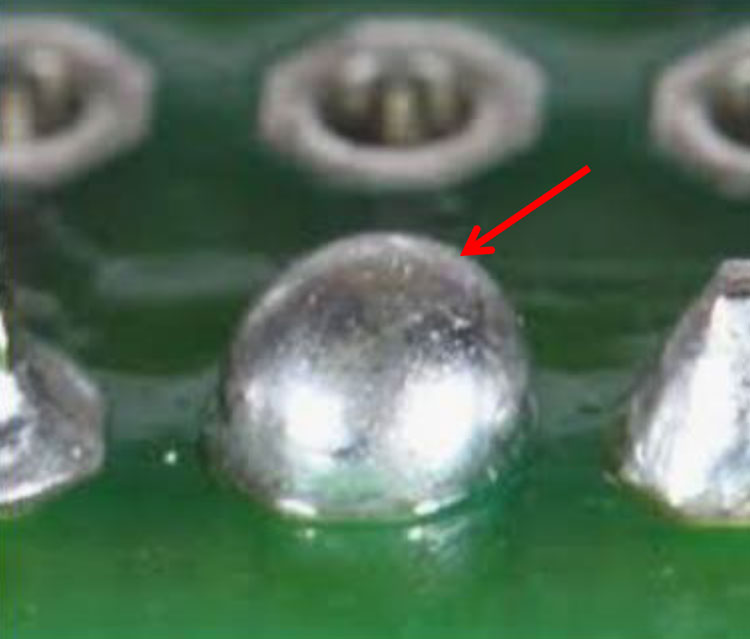

Excess Solder (2)

Cause: Excess solder was applied to the connection during soldering.

adafruit.com

Correction: Remove excess solder using fluxed

solder wick and soldering iron or a solder sucker.

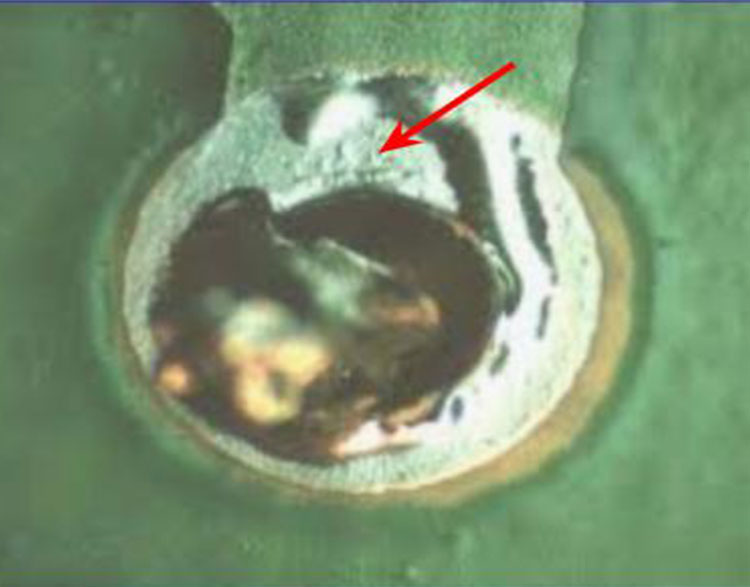

Insufficient Wetting (3)

Cause: Insufficient heating of the original solder connection.

NASA

Correction: Flux the connection on both side of

the PCB. Connect both the pin and pad with a

soldering iron and reflow. Add solder as

necessary.

Poor Wetting (4)

Cause: Surface contamination on the soldered surface.

visioneng.com

Correction: Clean both sides of the PCB with PCB

cleaner and brush. Flux both sides and reflow from the

bottom side. Add solder as required.

Solder Tear (5)

Cause: During solder solidification, solder may separate at the grain

boundary as it contracts. More common in lead free solders.

NASA

Correction: IPC-610H states there is no defect

associated with this anomaly provided the

connection meets all other acceptance criteria.

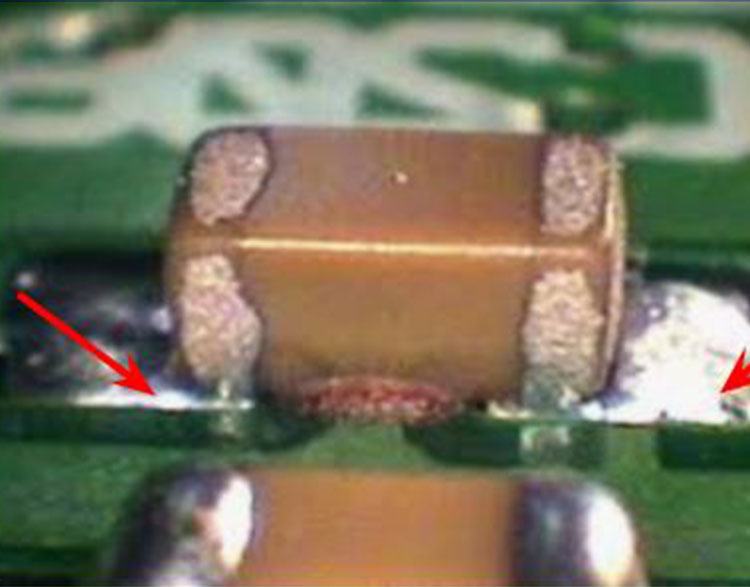

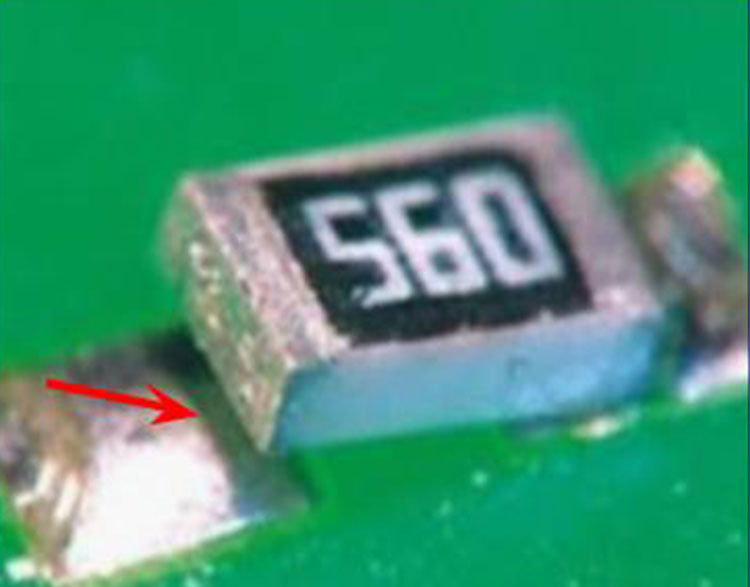

Poor Wetting (6)

Cause: Poor solder wetting/contamination

on the component/land terminations.

visioneng.com

Clean the component and both ends with

PCB cleaner and brush. For resistors, flux and reflow

each end. Add solder as necessary. For chip caps, use

hot air reflow.

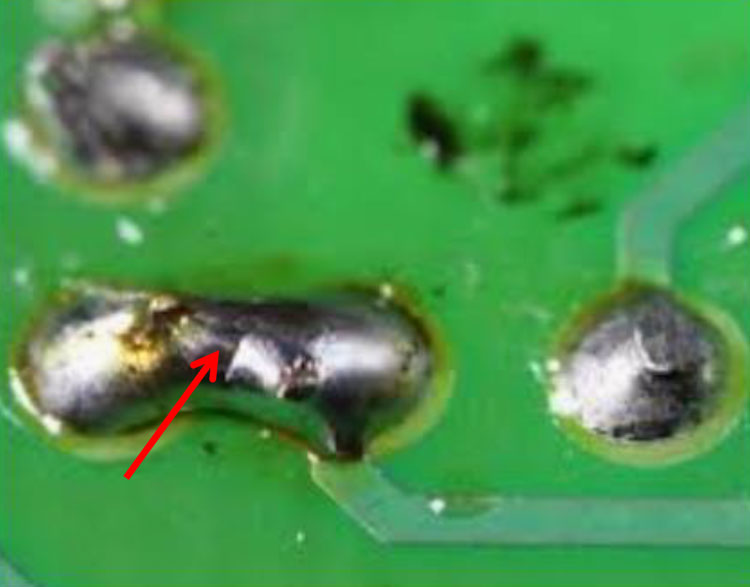

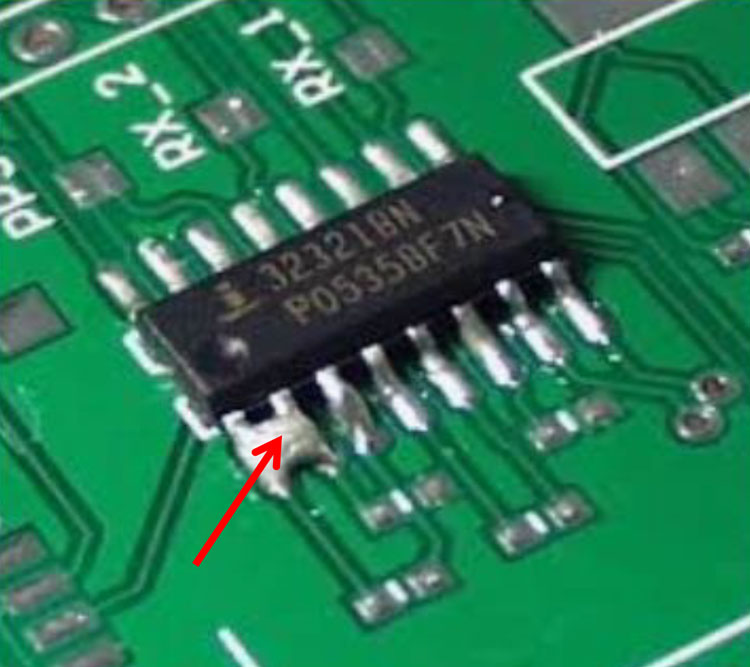

Solder Bridge (Short) (7)

Cause: Excessive solder between adjacent leads.

Pimoroni, Youtube-Androkavo

Correction: Flux both connections. Contact soldering iron tip onto

both leads to reflow solder and eliminate solder bridge. Clean both

leads of residual flux.

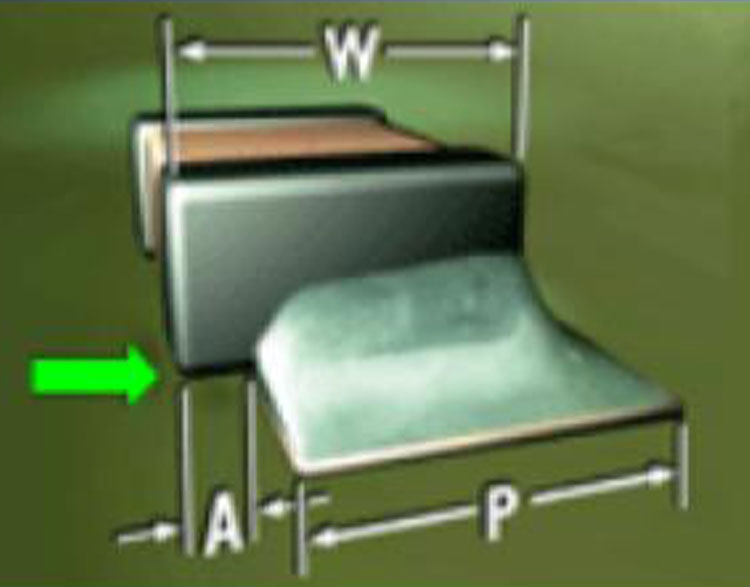

Chip Component Side Overhand "A" (8)

Cause: Incorrect side placement of the chip component

on it's mounting pads.

NASA

Correction: IPC-610H specifies Maximum Side Overhang

of 50%(W) for Classes 1 and 2.

Insufficient Solder (9)

Cause: Insufficient solder application during hand soldering.

autodesk.com

Correction: IPC-J-STD-001H specifies minimum solder filler height

on 1, 2, 3 and 5-sided chip components for

Class 1 and 2 applications.

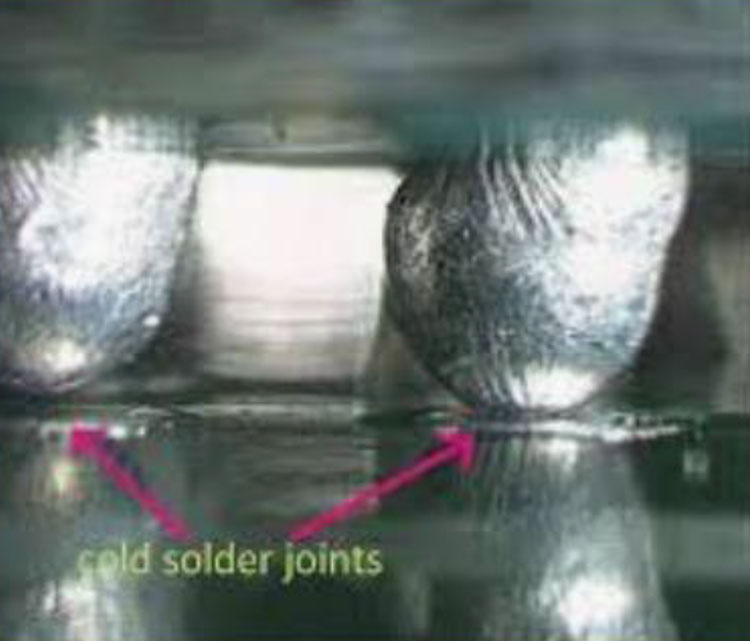

BGA Cold Solder Joints/Open Joints (10)

Cause: Insufficient heating of the BGA solder balls during BGA reflow (melting).

emerald.com

Correction: BGA Cold Solder and Open connections

are not repairable. BGA must be removed and

replaced with new or re-balled BGA.

Solder Short (11)

Cause: Application of excess solder during hand soldering.

autodesk.com

Correction: Flux the connection and use a soldering iron to

draw off excess solder. Or, remove the excess solder

using solder wick and soldering iron.

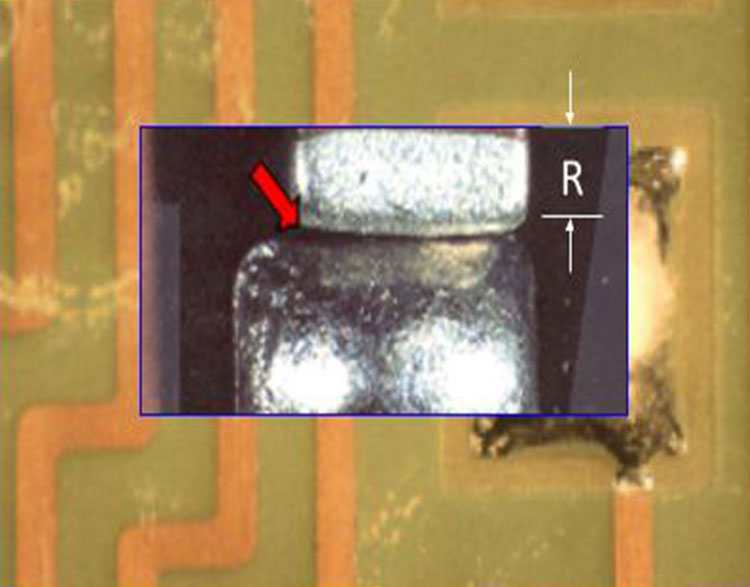

Insufficient Fillet Height (12)

Cause: Insuffiecient solder applied to chip

component end joint termination.

NASA

Correction: For Classes 1 and 2, J-001H requires that solder

be evident on the vertical surface of the termination.

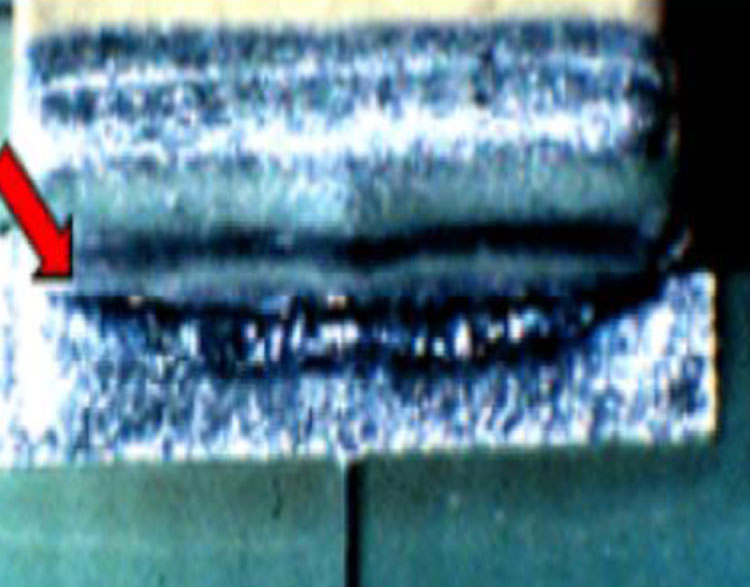

Cold Solder - Solder Paste (13)

Cause: Incomplete reflow (melting) of solder

paste balls during the reflow cycle.

NASA

Correction: Flux the lead, pad, and topside. Reflow lead

and pad by concurrent contact with the soldering iron.

Insufficient Wetting (14)

Cause: Solder has not wetted the pin and

partially wetted the pad.

adafruit.com

Correction: Flux the lead/pad. Verify even heating and

reflow of the lead and pad by concurrent contact with

the soldering iron. Clean both sides.

Tombstoned Component (15)

Cause: Imbalance of solder joint surface tension in molten

solder causes the "stronger" joint (right side) to lift the

component off the board, creating the "tombstone".

cadence.com

Correction: Correct this defect by fluxing and reflowing the chip

component using hot air or thermal tweezers (not on chip caps).

Or, alternate reflow of fluxed chip terminations via soldering iron.

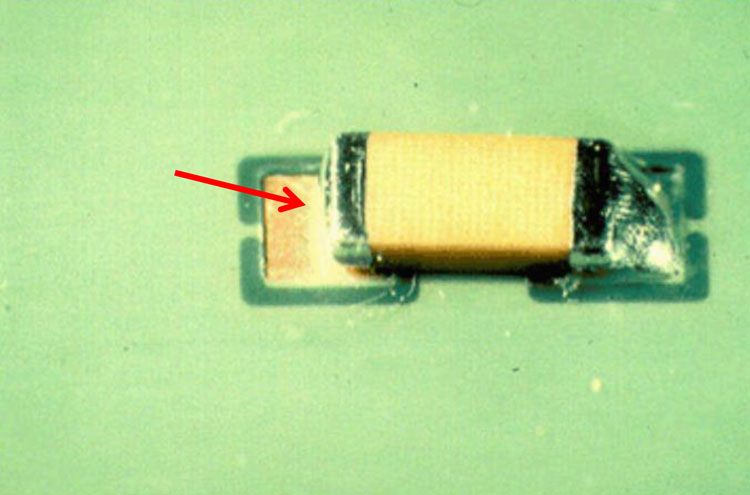

Chip Component End Overlap (16)

Cause: Misplacement of the chip component end

placement on its mounting pads.

EPEC

Correction: J-001H requires "Minimum End Overlap" for

classes 1 and 2.

CONTACT AEIC

AEIC provides IPC CIS certifications to wide range of clients. These include military contractors, consumer electronic suppliers, OEM & EMS suppliers, and individuals seeking personal certifications.